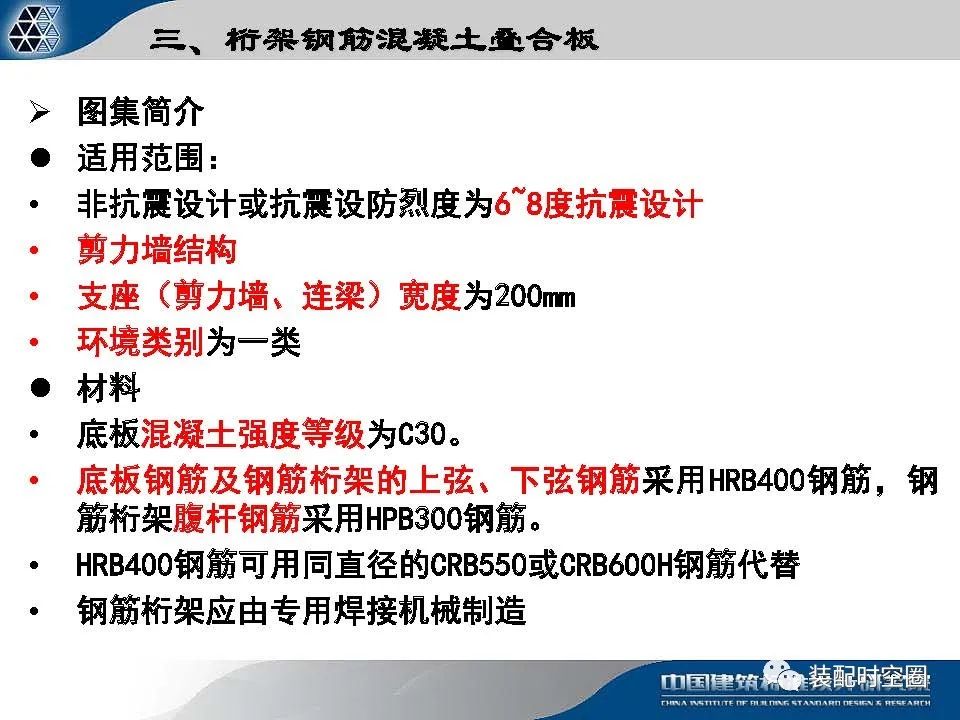

● scope of application: 1 Non seismic design or seismic design with seismic fortification intensity of 6-8; 2.

Shear wall structure; 3.

The width of bearing (shear wall and coupling beam) is 200mm; 4.

The environmental category is class I.

● material: 1 The strength grade of bottom slab concrete is C30.

2.

HRB400 reinforcement shall be used for bottom plate reinforcement and upper and lower chord reinforcement of reinforcement truss, and hpb300 reinforcement shall be used for web reinforcement of reinforcement truss.

3.

HRB400 reinforcement can be replaced by crb550 or crb600h reinforcement with the same diameter.

4.

The reinforcement truss shall be manufactured by special welding machinery.

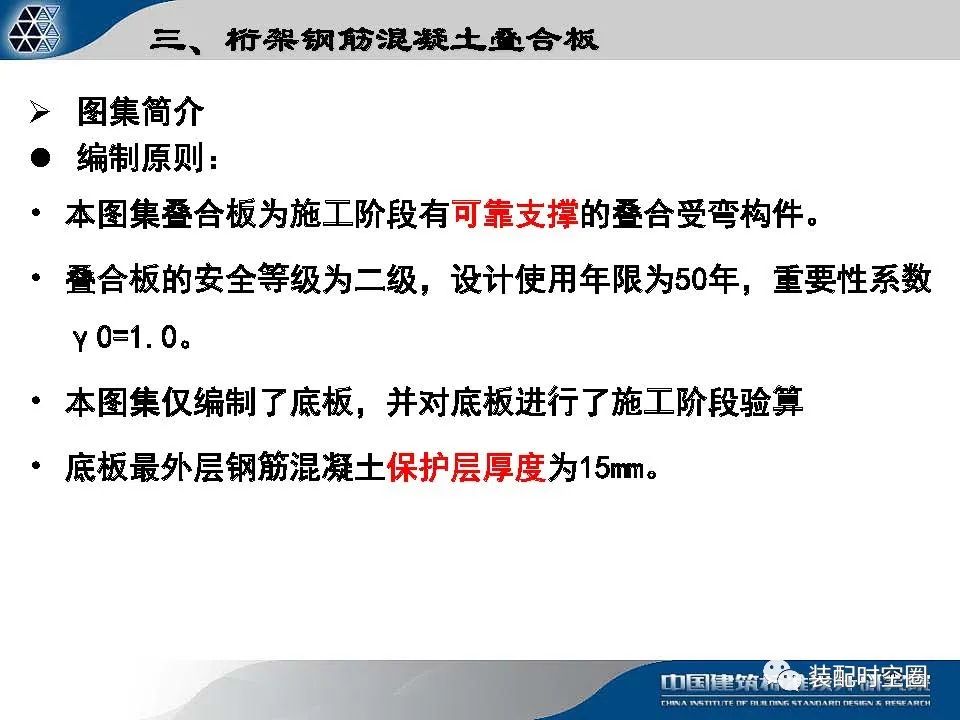

● preparation principle: 1 The composite plate in this atlas is a composite flexural member with reliable support in the construction stage.

2.

The safety level of the laminated plate is level II, the design service life is 50 years, and the importance coefficient Y0 = 1.0.

3.

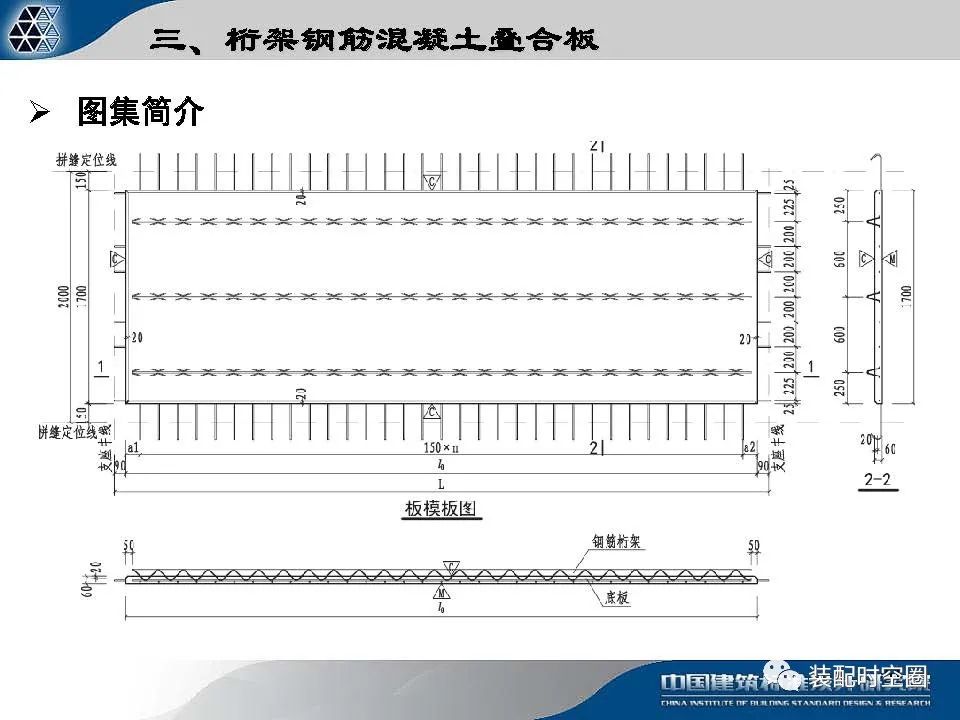

Only the bottom plate is prepared in this atlas, and the checking calculation at the construction stage is carried out for the bottom plate.

4.

The thickness of the outermost reinforced concrete protective layer of the bottom plate is 15mm.

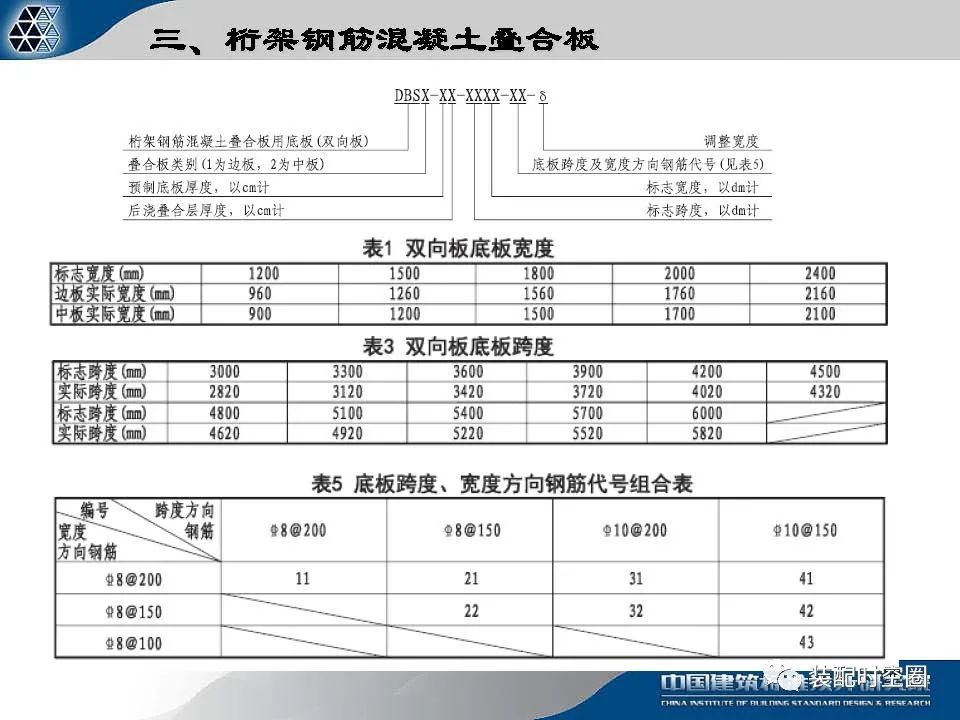

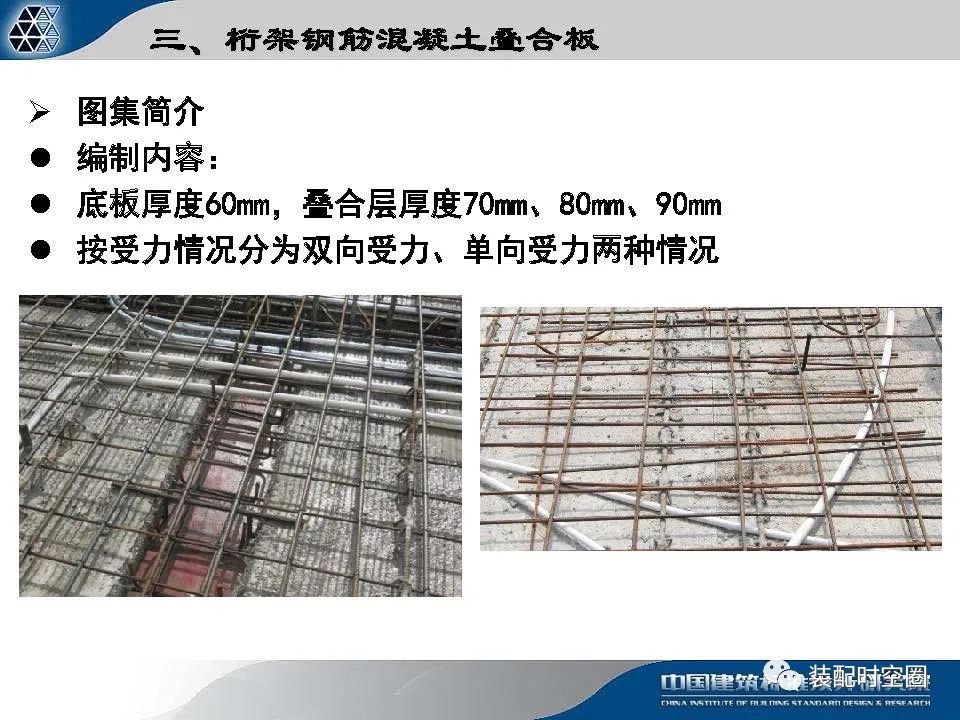

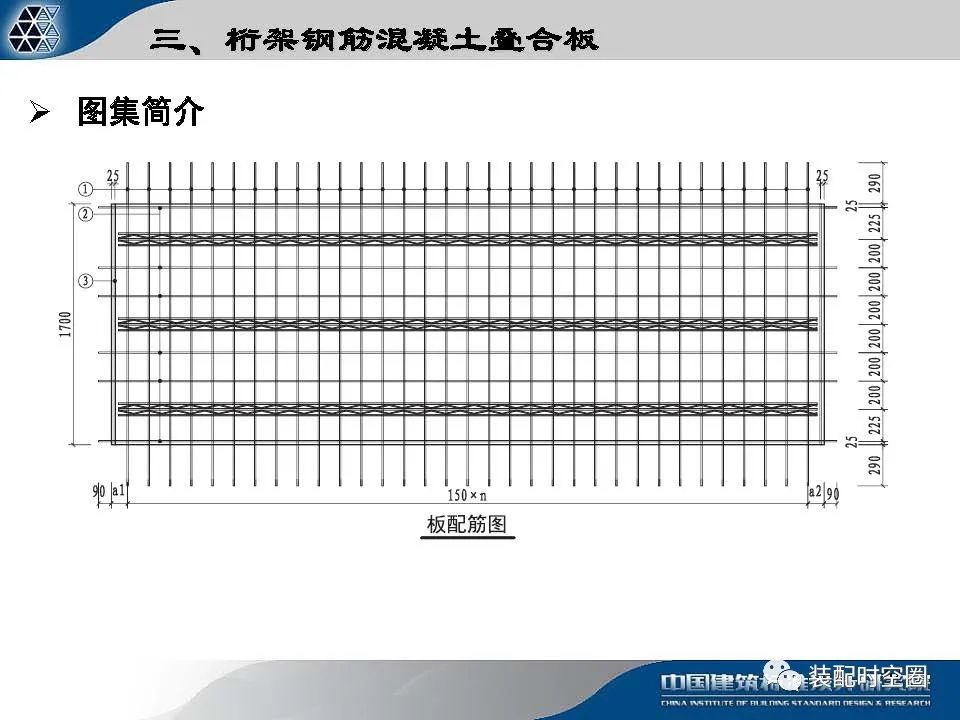

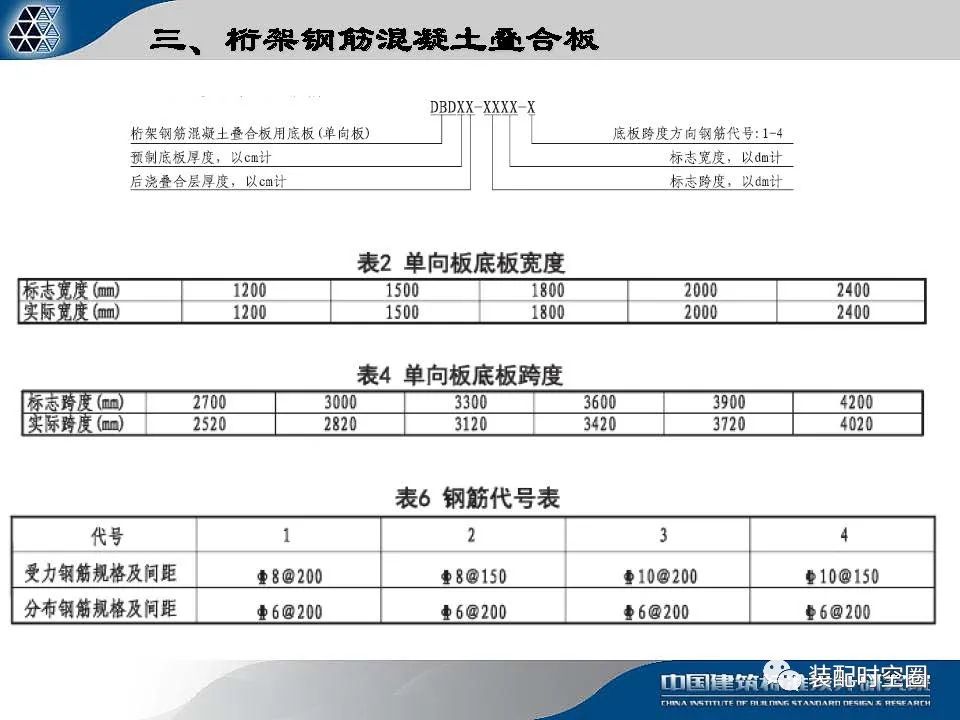

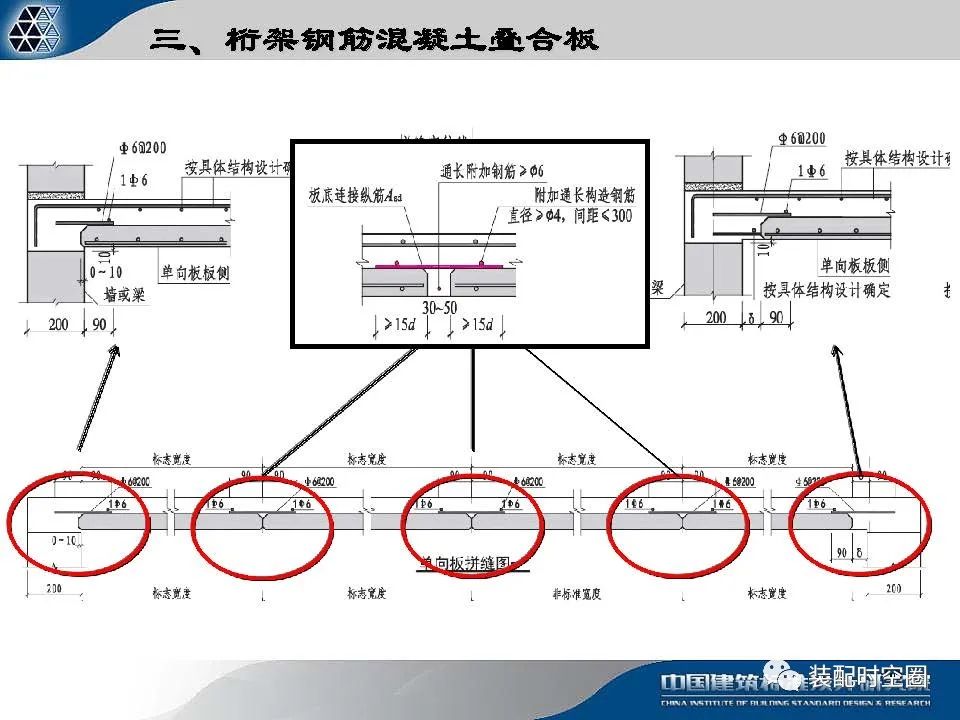

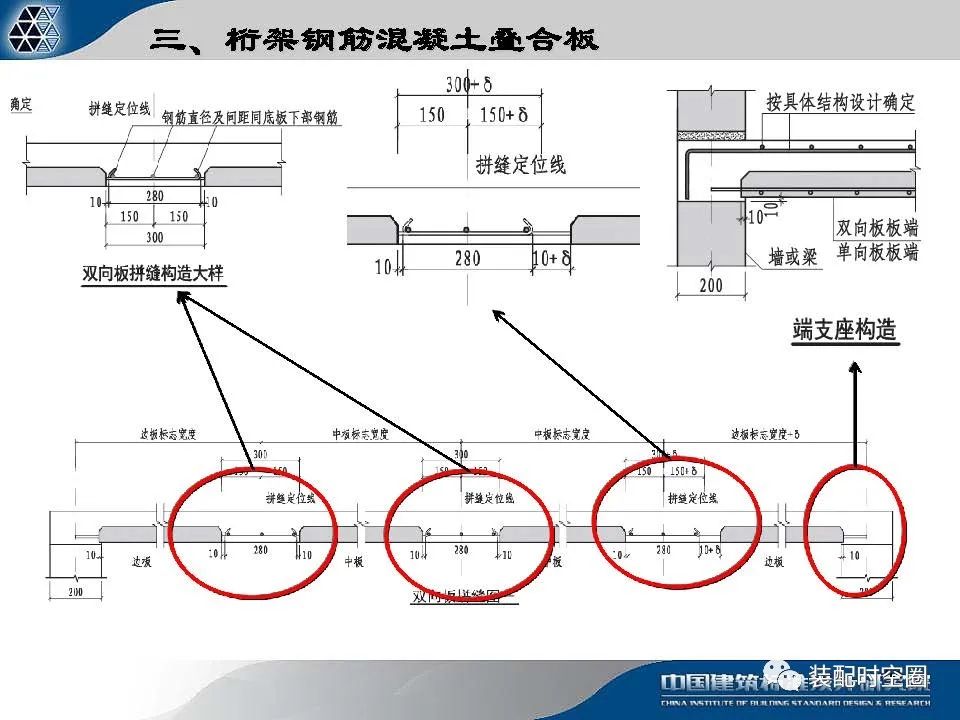

● preparation content: the thickness of bottom plate is 60m, and the thickness of laminated layer is 70m, 80mm and 90mm; According to the stress conditions, it can be divided into two situations: two-way stress and one-way stress.

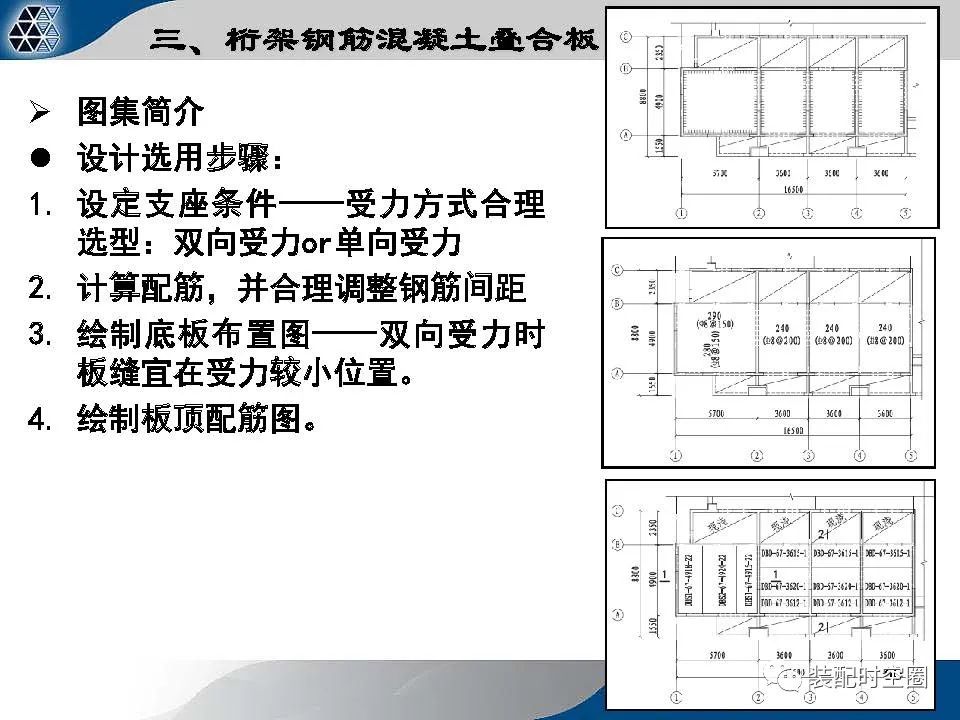

● design selection steps: 1 Set bearing conditions – reasonable selection of stress mode: two-way stress or one-way stress; 2.

Calculate the reinforcement and reasonably adjust the reinforcement spacing; 3.

Draw the layout of the bottom plate – the plate joint should be at the position with less stress when two-way stress is applied; 4.

Draw the reinforcement drawing of slab top.

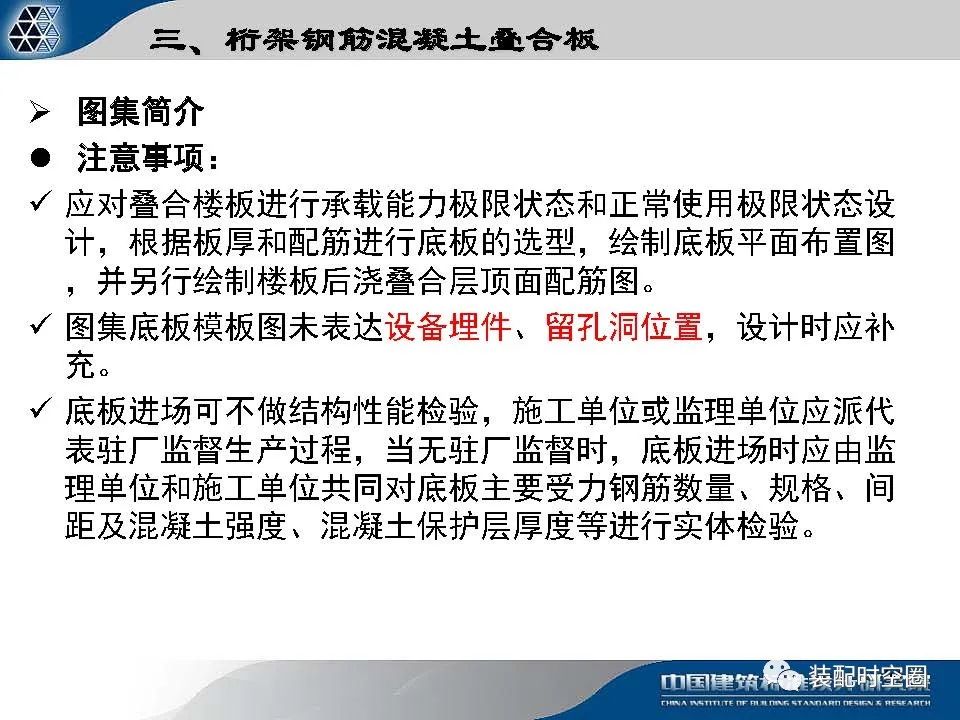

● precautions: √ design the bearing capacity limit state and normal service limit state of the laminated floor, select the base plate according to the plate thickness and reinforcement, draw the floor layout plan, and separately draw the reinforcement drawing of the top surface of the post cast laminated layer of the floor.

√ the position of equipment embedded parts and reserved holes is not shown in the bottom plate formwork drawing of the atlas, which shall be supplemented in the design.

√ the structural performance inspection is not required for the base plate mobilization.

The construction unit or the supervision unit shall send representatives to the factory to supervise the production process.

When there is no factory supervision, the supervision unit and the construction unit shall jointly carry out physical inspection on the quantity, specification, spacing, concrete strength and concrete protective layer thickness of the main stressed reinforcement of the base plate.

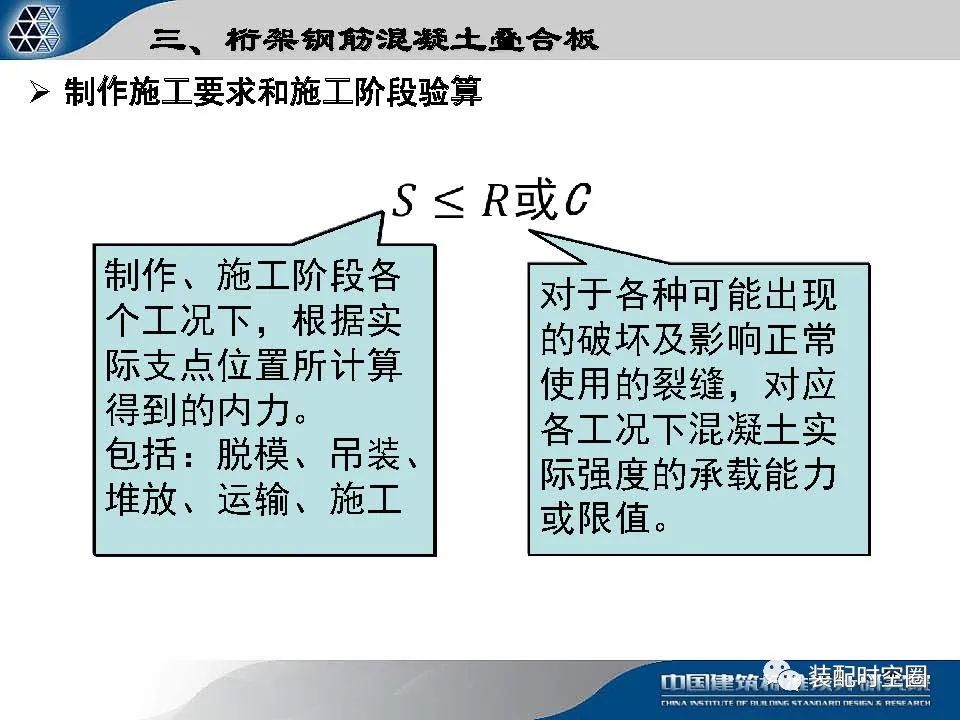

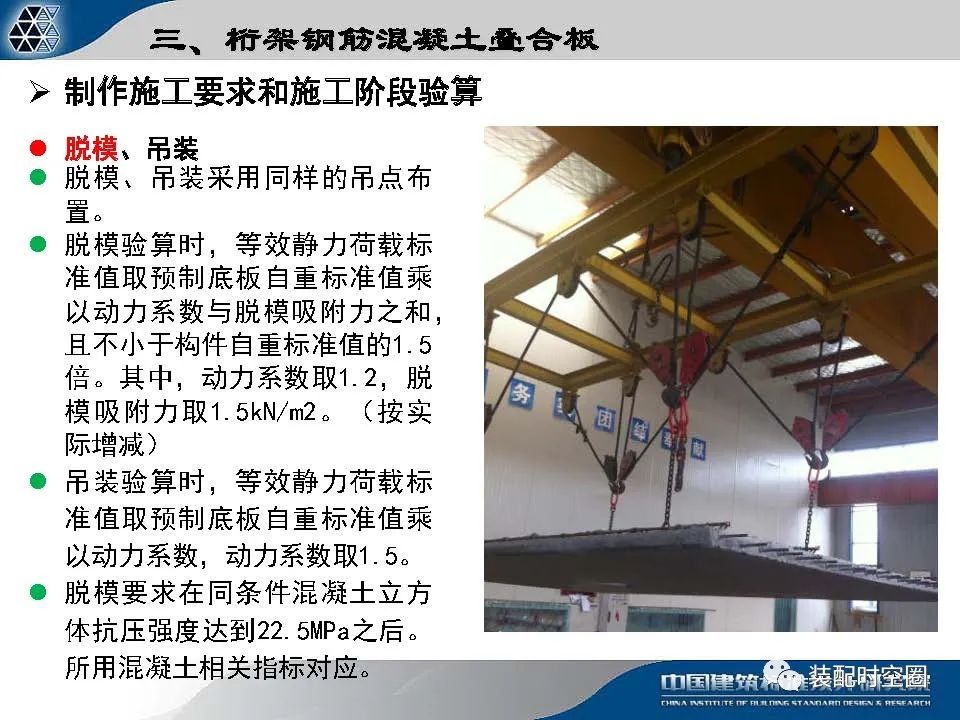

Fabrication and construction requirements and checking calculation at construction stage – demoulding ● the same lifting points shall be used for demoulding and hoisting.

● during demoulding checking calculation, the standard value of equivalent static load shall be the sum of the standard value of self weight of precast base plate multiplied by the dynamic coefficient and demoulding adsorption force, and shall not be less than 1.5 times of the standard value of self weight of components.

Wherein, the dynamic coefficient is 1.2 and the demoulding adsorption force is 1.5kn / ㎡.

(based on actual increase or decrease).

● during hoisting checking calculation, the standard value of equivalent static load shall be the standard value of self weight of precast bottom plate multiplied by the dynamic coefficient, and the dynamic coefficient shall be 1.5.

● demoulding is required after the compressive strength of concrete cube under the same conditions reaches 22.5MPa.

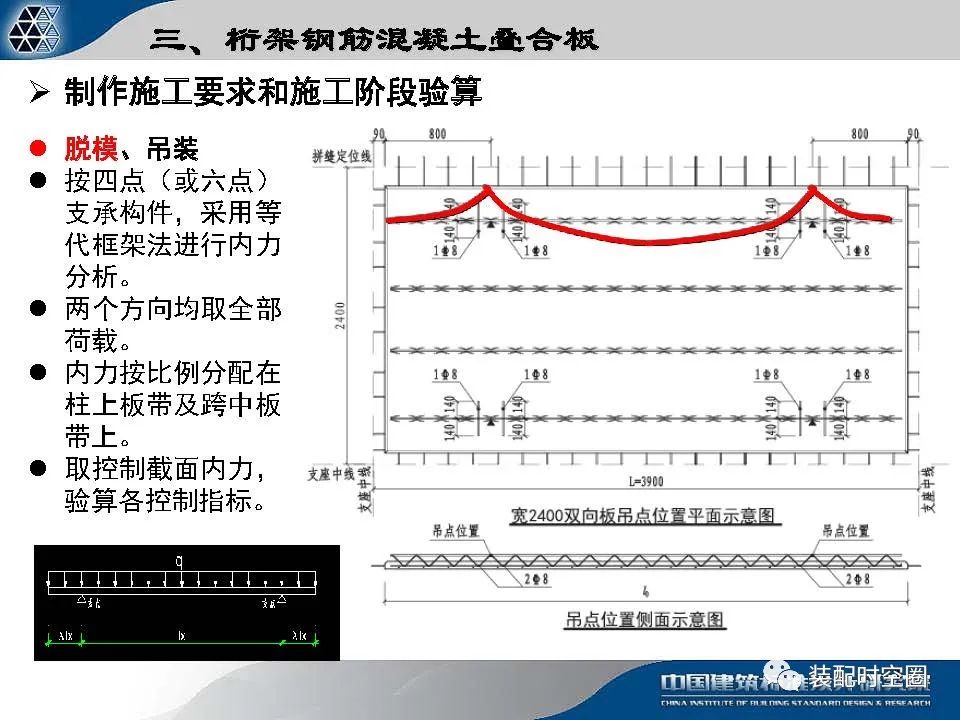

Demoulding and hoisting ● internal force analysis shall be carried out by equivalent frame method according to four point (or six point) supporting members.

● take all loads in both directions.

● the internal force is distributed on the column strip and mid span strip in proportion.

● take the internal force of the control section and check each control index.

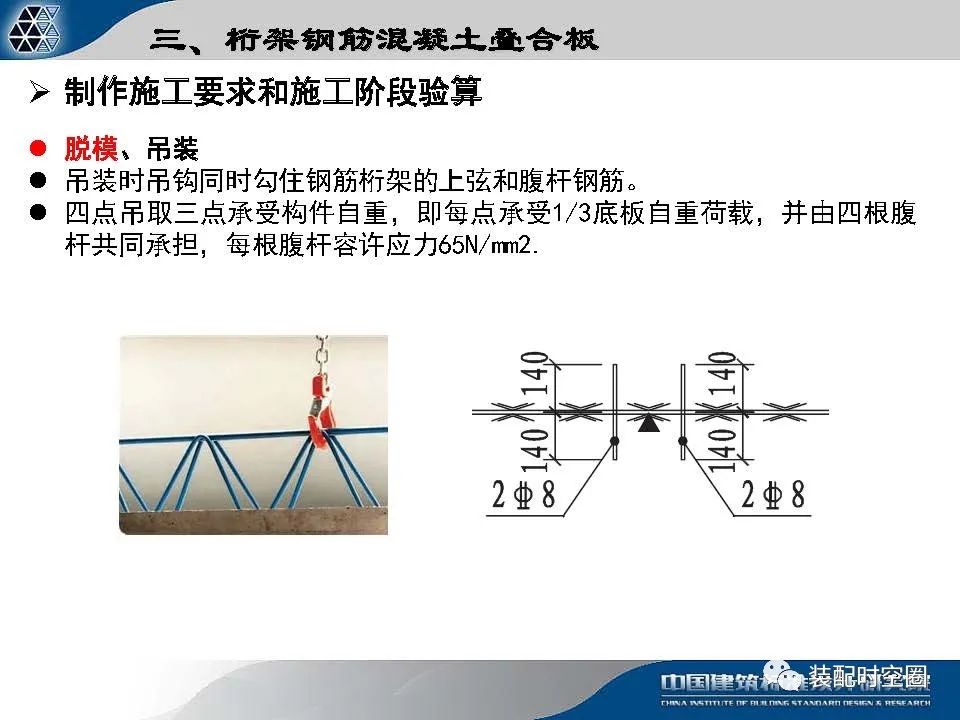

● during hoisting, the hook shall hook the upper chord and web bar reinforcement of the reinforcement truss at the same time.

● lift from four points and bear the dead weight of components at three points, that is, each point bears 1 / 3 of the dead weight load of the bottom plate, which is jointly borne by four web members, and the allowable stress of each web is 65N / ㎡.

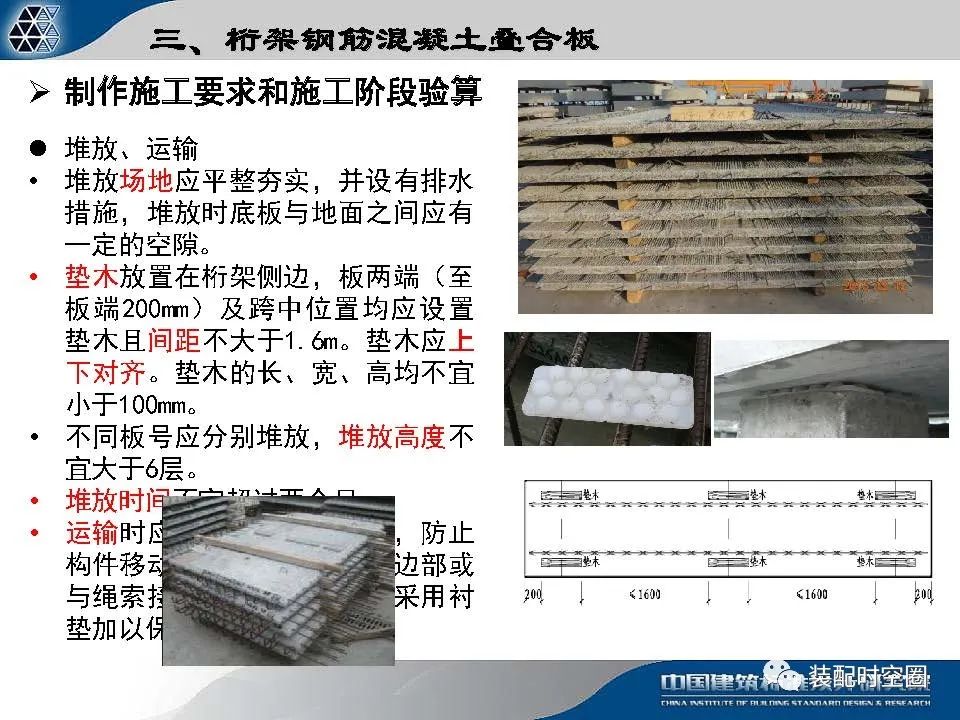

● the construction and installation can be carried out only after the strength of the base plate concrete reaches 100% of the design strength grade value.

● before the bottom plate is in place, a temporary support composed of vertical brace and beam shall be set in the span and 500mm away from the support.

● when the axle span l < 4.8m, a support shall be set in the span; Axle span 4.8m ≤ L ≤ 6.8m Two supports are set in the span when M.

● the top surface of the support shall be leveled reliably to ensure the flatness of the bottom surface of the base plate.

● in multi-storey buildings, the vertical bracing of each floor should be set on a vertical line.

Construction temporary support ● the removal of temporary support shall comply with the provisions of relevant current national standards.

Generally, it shall be supported for two layers.

● the uniformly distributed load of construction temporary support shall not be greater than 1.5kn / ㎡.

If the load is uneven, the converted uniformly distributed load within the veneer range shall not be greater than 1.0kn / ㎡, otherwise strengthening measures shall be taken.

(the uniformly distributed construction load does not include the self weight of uniformly distributed laminated concrete).

● the bottom plate shall be protected from impact during construction…